Pipeline Integrity

At Integrity Specialists your satisfaction is our number one concern. We strive to give you the technicians that you request. This means building solid relationships, which is mutually beneficial. Our technicians are trained to gather high quality useful data during the direct assessment.

Our complete reporting package can be tailored to your specific inspection needs. All details for the RCA (Root Cause Analysis) are included in our reporting. Starting with a general site assessment, soil resistivity and PH, coating condition, pipe to soil measurements, and pipe PH readings. Detailed photos are included with every report. Reports are delivered in an efficient and timely manner.

ADVANCED SERVICES

Eddyfi

Spyne, an adaptable surface Eddy Current Array (ECA) screening tool, is specifically engineered to maximize productivity for the detection of Stress Corrosion Cracking (SCC) cracks, subsurface defects, and pitting in various critical components such as high-pressure gas pipes, vessels, tanks, pipelines, and more. Learn more here.

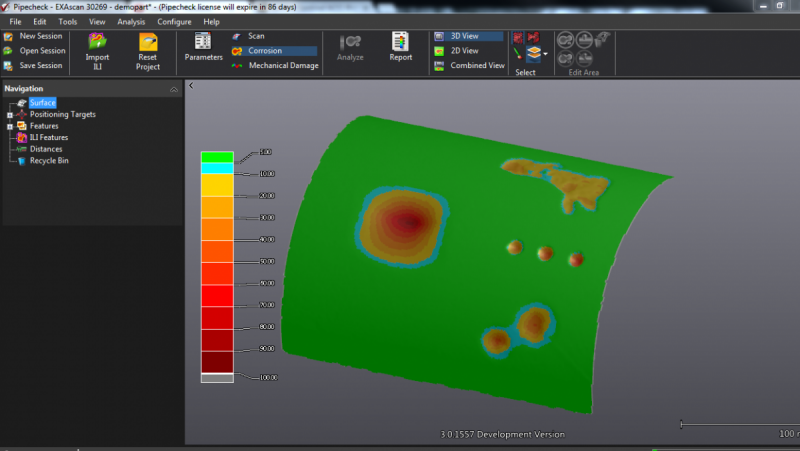

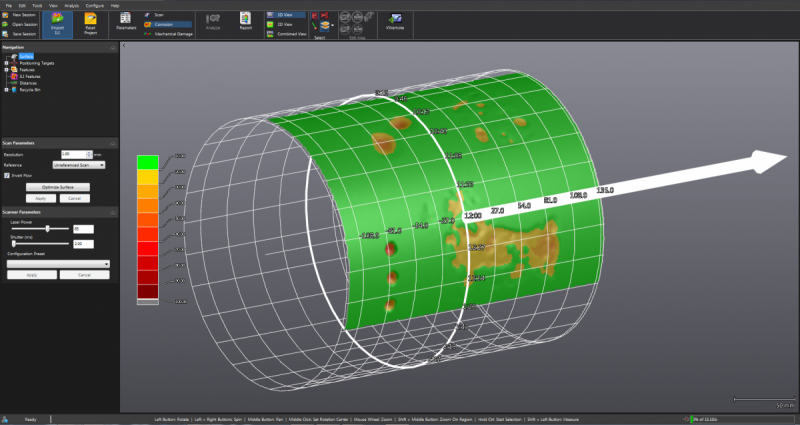

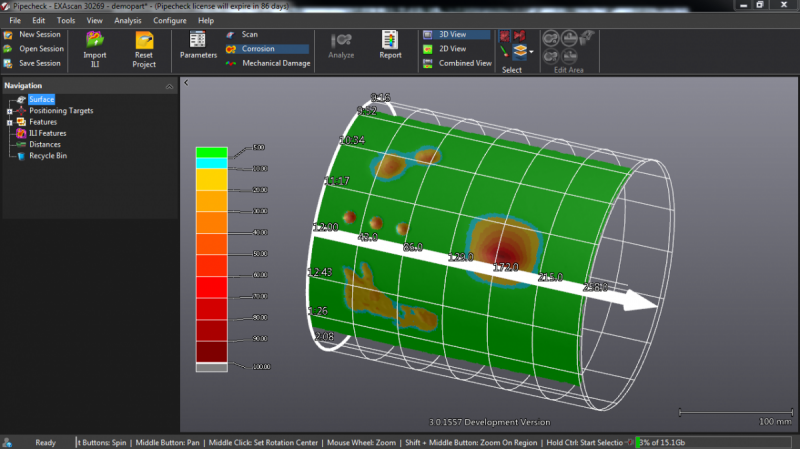

Creaform Laser Scanning

Creaform scans for corrosion, dents, buckles, and defects. Learn more here.

Automated UT Scans

Here we scan new construction girth welds and corrosion.

OTHER SERVICES

Traditional NDT Methods

Magnetic Particle (MT)

Dye Penetrant (PT)

Ultrasonic (UT) Thickness and Shear wave

Phased Array (PAUT)

ILI Verification/Direct Assessments

Internal and external corrosion

Remaining Strength calculations

Dents and wrinkle bends

Hard spot validations

Stress Corrosion Cracking (SCC) verification and sizing

Long seam and Girth weld features

3rd Party damage assessments

Complete repair and recoat documentation

Recoating project support

Material Verification

Learn more here.

ASNT (American Society of Non-Destructive Testing)

Level III training and procedure reviews